Background

TRH approached us with their fleet of bulk trucking equipment and years of experience. They had built strong relationships with their clients and were known for quickly responding to their needs.

They transported everything from food products to different types of liquid chemicals. With a wide range of customers, they wanted to keep anticipating what their clients needed and deliver high-quality service as they grew.

However, they were having trouble with outdated paper systems and different accounting and operations tools. They needed a more organized solution to help them expand their business smoothly.

ATS Innovation

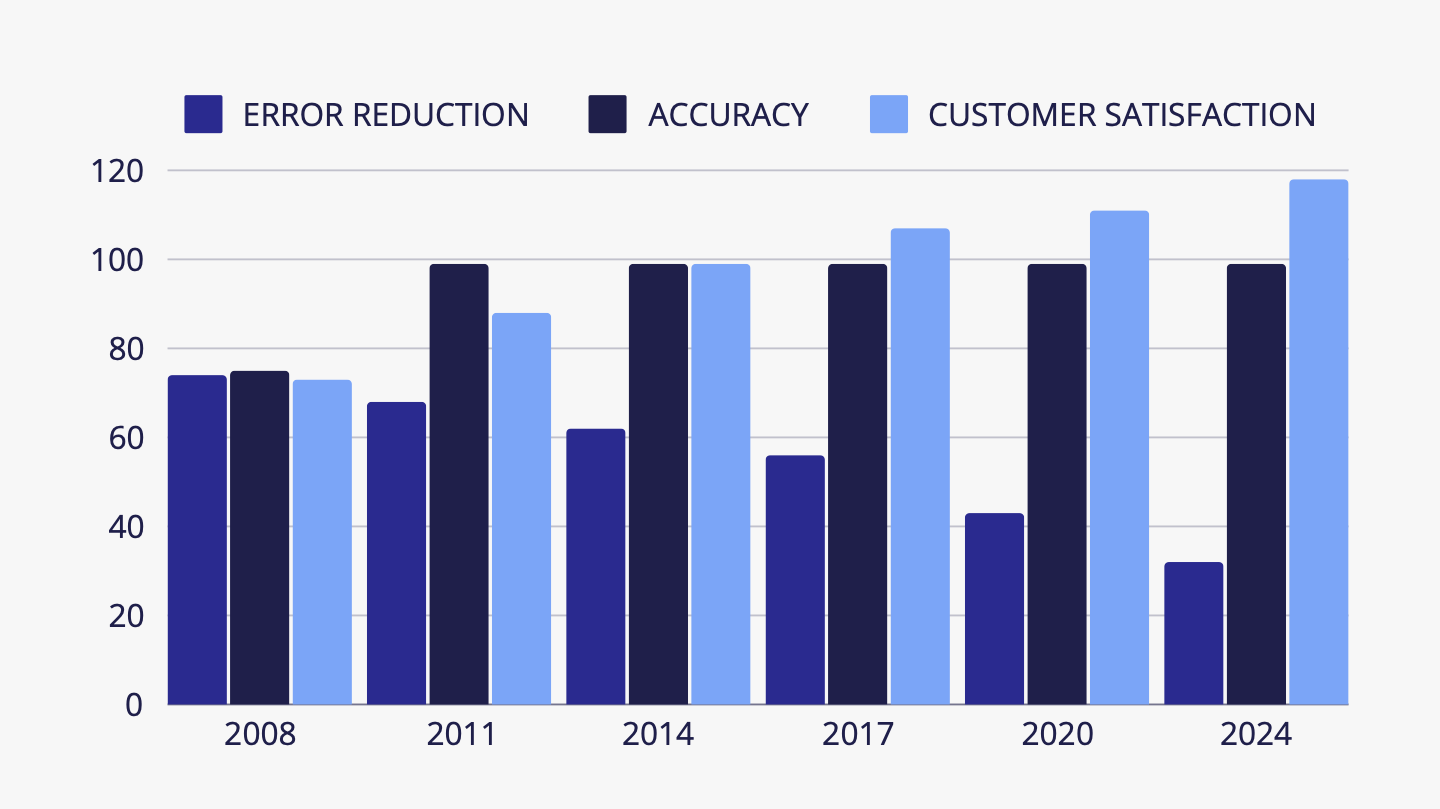

ATS began working with TRH in 2008 to improve their original homegrown software. This partnership quickly led to better operations and set the stage for more software upgrades.

By 2011, we rolled out RIMS, our special database-driven software for transloading. This change greatly improved operations by reducing paperwork by 30% and completely eliminating double data entry. This saved TRH between 40 to 80 hours of manual work each week.

Over our 15 years of working together, TRH has experienced a 37% increase in overall efficiency.

ATS Comprehensive Solutions

A timeline view of improvements, enhancements, and completely new software integrations to keep up with the growing demand of TRH's transloading operations.

.png?width=834&height=406&name=MP%20and%20PTL%20(2).png)